Qnergy, a proven methane abatement solutions provider and foremost manufacturer of clean, reliable, electric power utilizing Stirling engine technologies, announced independent validation of its superior methane destruction performance.

The competitive study was sponsored by CanERIC, the Canada Emission Reduction Innovation Consortium of researchers and end-users dedicated to developing, validating, and employing technologies for critically needed, novel, high performance, and cost-effective technologies to address the global emissions reduction challenge.

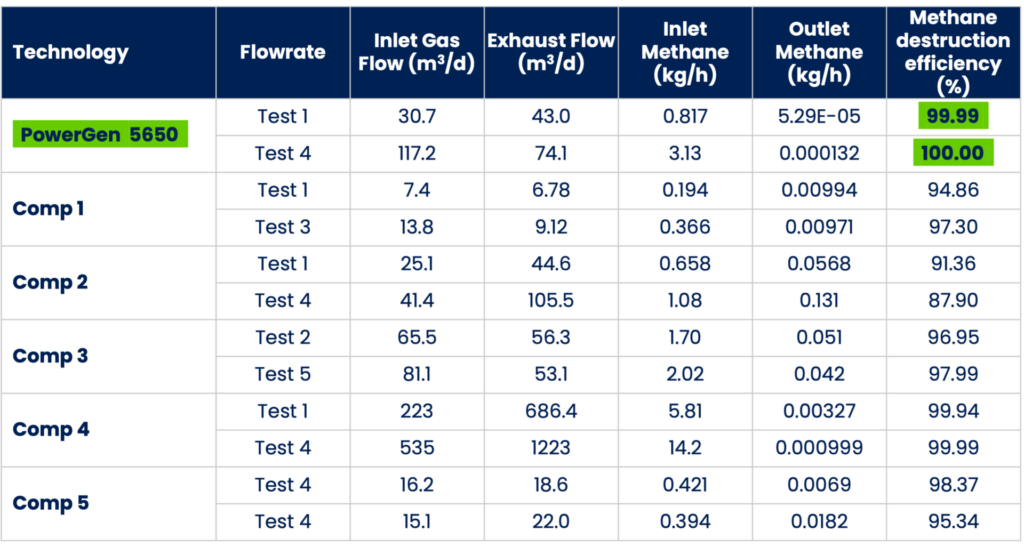

The project, Electrical Generation Technology Showdown, tested the performance of six technology product offerings on methane destruction efficiency. Qnergy was the only product tested to achieve 100% methane destruction under test conditions (see Table).

In addition to high operating costs to maintain, traditional internal combustion engines (ICE) suffer from “methane slippage,” the release of methane into the atmosphere. Over time, this methane slippage is significant, along with the release of other greenhouse gases due to incomplete combustion.

Qnergy, with its novel, non-rotary, no lubricant, no OpEx required, innovative and award nominated, free piston Stirling engine technology, offers many advantages over ICE solutions in providing the best in class GHG abatement performance and useful power wherever needed.

”We are proud for being able to prove our ability to completely turn methane into useful energy without any ‘methane slip’” said Ory Zik, Qnergy’ CEO. “While it may be non-intuitive, at a global warming factor of 85 every pound of methane is translated to 85 pounds of carbon dioxide equivalent,” he added.